Guangdong Qs-Mag Technology Co., Ltd. was established in 2013.It is a national high-tech enterprise that adheres to contracts and valuescredit. It is located in Dongguan, Guangdong Province, which known asthe world's factory. The company has multiple practical capabilities suchas independent research and development, production, and sales ofmagnetic materials and products.

50

mil.7000

㎡+1000

㎡900

ton+30

+128

unit

A single sided magnet refers to a magnet that has magnetic properties on one side and weaker magnetic properties on the other. The method is to wrap one side of the double-sided magnet with a specially treated galvanized iron sheet, so that the magnetic properties of the wrapped side will be shielded, refracted to the other side, and the magnetic properties of the other side will be enhanced. Single sided magnets can be applied in many industries, such as printing and packaging, tea boxes, gift boxes, luggage and leather goods, etc.

Also known as arc magnets or curved magnets, they are the most common type of permanent magnet motor magnet. These magnets are designed as single or double arc according to needs and are located around the motor stator to provide a magnetic field. Commonly used in various permanent magnet DC motors.

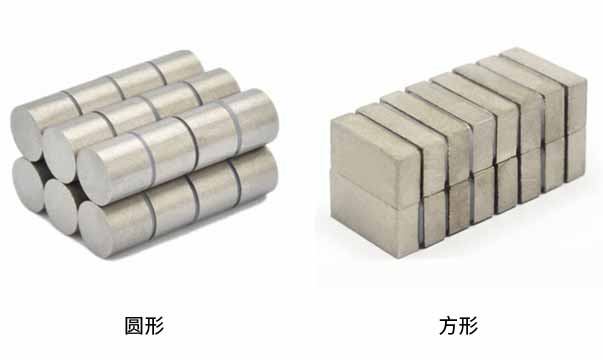

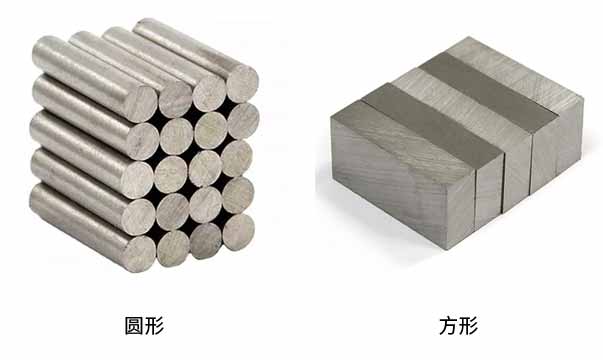

The advantage of a square magnet is its high cost-effectiveness. It is a permanent magnet material based on the intermetallic compound Nd2Fe14B, which has good mechanical properties. At the same time, it adjusts its chemical composition during the production process and adopts surface coating treatment methods to expand its applicability.

Neodymium magnet, also known as NdFeB magnet, is a tetragonal crystal composed of neodymium, iron, and boron (Nd2Fe14B). In 1982, Sumitomo Special Metal's Sagawa Shinzo discovered neodymium magnets. The magnetic energy product (BHmax) of this type of magnet is greater than that of samarium cobalt magnets, making it the largest magnetic energy product in the world at that time. Later, Sumitomo Special Metals successfully developed the powder metallurgy process, while General Motors successfully developed the melt spraying process, which can prepare neodymium iron boron magnets. This type of magnet is a permanent magnet with magnetic properties second only to absolute zero degree holmium magnets, and is also the most commonly used rare earth magnet. Neodymium iron boron magnets are widely used in electronic products, such as hard drives, mobile phones, headphones, and battery powered tools.

To avoid corrosion damage, it is necessary to perform protective treatment on the surface of permanent magnet materials during use, such as electroplating with gold, nickel, zinc, tin, and spraying epoxy resin on the surface.

Ferrite magnets belong to sintered permanent magnet materials, composed of barium and strontium ferrite. This type of magnetic material not only has strong demagnetization resistance, but also has the advantage of low cost. Ferrite magnets are hard and brittle, requiring special mechanical processing techniques. Due to its orientation in the manufacturing direction, its opposite magnet needs to be magnetized in the direction it is taken, while its like magnet can be magnetized in any direction because it has no orientation, although slightly stronger magnetic induction is often found on the smallest side of the pressure surface. The magnetic energy product range is between 1.1MGOe and 4.0MGOe. Due to its low cost, ferrite magnets have a wide range of applications, from motors and speakers to toys and handicrafts, making them the most widely used permanent magnet material at present.

Produced using powder metallurgy method, with low residual magnetism and low recovery magnetic permeability. The magnetic circuit structure has high coercivity and strong resistance to demagnetization, making it particularly suitable for dynamic working conditions.

Rubber magnet is a type of ferrite magnetic material series, which is made by combining bonded ferrite powder with synthetic rubber through extrusion molding, rolling molding, injection molding, and other processes to produce a soft, elastic, and twisted magnet. It can be processed into strips, rolls, sheets, and various complex shapes.

Rubber magnets are composed of magnetic powder (SrO6Fe2O3), polyethylene (CPE), and other additives (EBSO, DOP), and are manufactured by extrusion and rolling. Rubber magnetic materials can be isotropic or anisotropic, made of ferrite magnetic powder, CPE, and certain trace elements, and can be bent, twisted, and rolled. It can be used without further mechanical processing, and can also be shaped according to the required size. Rubber magnets can also be made of PVC, back glue, UV oil, etc. according to customer requirements. Its magnetic energy product ranges from 0.60 to 1.50 MGOe.

The application fields of rubber magnetic materials include refrigerators, message display racks, fasteners used to fix objects to metal bodies for advertising, and magnetic sheets used in toys, teaching instruments, switches, and sensors. Mainly used in industries such as micro and special motors, refrigerators, disinfection cabinets, kitchen cabinets, toys, stationery, advertising, etc.

Samarium cobalt magnet, also known as Samarium cobalt magnetic steel, Samarium cobalt permanent magnet, Samarium cobalt permanent magnet, rare earth cobalt permanent magnet, etc. It is a magnetic material made by mixing samarium, cobalt, and other rare earth metals into alloys, crushing, pressing, and sintering. It has a high magnetic energy product, extremely low temperature coefficient, and a maximum working temperature of 350 ℃, with no negative temperature limit. When the working temperature is above 180 ℃, its maximum magnetic energy product, temperature stability, and chemical stability exceed that of neodymium iron boron permanent magnet materials.

Samarium cobalt magnets have strong corrosion resistance and oxidation resistance; So it is widely used in aerospace, national defense and military industry, microwave devices, communication, medical equipment, instruments, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes, etc.

Aluminum nickel cobalt permanent magnet is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metal elements. The composition of its metal components is different, and its magnetic properties are also different, resulting in different uses. There are three different production processes for aluminum nickel cobalt permanent magnets: casting, sintering, and bonding. The casting process can be processed and produced into different sizes and shapes. Compared to the casting process, sintered products are limited to small sizes, resulting in small dimensional tolerances for the produced rough products and good casting processability. In permanent magnet materials, cast aluminum nickel cobalt permanent magnets have the lowest reversible temperature coefficient and can operate at temperatures above 500 degrees Celsius. Aluminum nickel cobalt permanent magnet products are widely used in various instruments and other high-temperature resistant applications.

NdFeB bonded permanent magnet material is made by adding NdFeB magnetic powder to the adhesive. Since the successful development of this material in 1988, its development has been quite rapid and its production has increased exponentially. As a high-performance permanent magnet material, it conforms to the trend of modern electronic products in the direction of short term, small, light, and thin development. Compared with sintered magnets, it can be formed in one go without the need for secondary processing and can be made into various complex shaped magnets, which is also incomparable to sintered magnets. Its application can greatly reduce the volume and weight of the motor.

The production and application development of bonded neodymium iron boron permanent magnet materials were relatively late, with limited application scope and small usage. They are mainly used in office automation equipment, electrical installation machinery, audio-visual equipment, instruments and meters, small motors and measuring machinery, and are widely used in fields such as mobile phones, CD-ROM, DVD-ROM drive motors, hard disk spindle motors HDD, other micro and special DC motors, and automation instruments and meters. In recent years, the application proportion of bonded neodymium iron boron permanent magnet materials in China is 62% for computers, 7% for the electronic industry, 8% for office automation equipment, 7% for automobiles, 7% for appliances, and 9% for others.

Guangdong QS-Mag Technology Co., Ltd Copyright:E-WIN